The Quest for the Best: Optimizing Phosphoric Acid Production

Global demand for P₂O₅ is steadily rising, fueled not only by the agricultural sector’s need for fertilizers but also by applications across technical and food industries. In parallel, environmental norms, particularly regarding emissions and recovery of pollutants, are getting stricter.

In this dual context of growth and sustainability, producers of phosphoric acid face a clear challenge: how to increase production volume and improve efficiency, while ensuring performance and minimizing environmental impact. At Prayon, this challenge is addressed through the combined strengths of Profile equipment and Prayon Technologies’ process expertise. Together, they provide integrated solutions to enhance volume, quality, and recovery across phosphoric acid plants worldwide.

The following case studies illustrate different ways in which these synergies have supported producers in meeting their evolving expectations.

Case Study 1: Raising Output in an Existing Plant

A producer operating a phosphoric acid plant for over 20 years, with abundant access to phosphate rock ambitioned to increase P₂O₅ output without significant new capital expenditure.

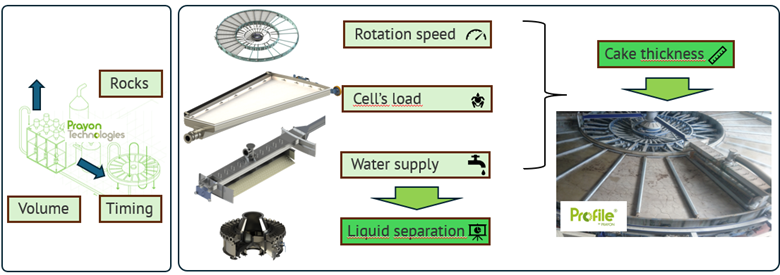

Prayon Technologies and Profile worked hand in hand, optimizing both process and mechanical parameters. On the process side, the attack reaction was adjusted to balance reaction timing and volume increase, improving reactor throughput.

On the mechanical side, Profile fine-tuned agitator performance, increased filter rotation speed adjusted wash volumes and optimized cell’s load to maximize separation efficiency with higher cake thickness (See below table 1).

Despite 10 to in operating costs on the Prayon filter- as harsher operating conditions accelerated wear , the outcome was impressive: a 25-27% increase in P₂O₅ production.

Case Study 2: Expanding Capacity with Limited Investment

In a plant commissioned in early 2000’s and already equipped with a large Prayon filter, our customer’s objective was to raise P₂O₅ production, with the potential to boost output by 40%.

Prayon responded by updating the process design and supplying proprietary Profile equipment to secure production capacity while guaranteeing low emissions. This included four agitators for the reactors, three for digestion, and a double scrubber tower.

The benefits were significant: an additionalof P₂O₅ per day, achieved with limited CAPEX compared to building a new line. The main compromise was the need for footprint extension, though the producer had space available. Importantly, the savings were substantial—around €3 million on filtration equipment alone.

Case Study 3A & 3B: Designing a Long-Lasting Plant

A new phosphoric acid factory linked to a phosphate mine aimed to secure quality, reliability, and long-term design capacity.

In Configuration 3A, Prayon Technologies acted as process licensor, supporting the producer throughout dimensioning, planning, and execution. Prayon Technologies guaranteed specific performance levels: insoluble P2O5 yield with agitators, soluble yield with the Prayon filter, 99.8% yield with the Praysep separator, and strict emission control at 5 mg/Nm³ of fluorine with the gas scrubber. This approach delivered a high-performing, future-proof production unit, which makes CAPEX profitable and sustainable for environment.

In Configuration 3B, Prayon equipment was integrated into a plant developed by another process technology provider. While no process guarantees were offered by Prayon, the producer benefited from proven equipment performance, renowned OEM reliability, and the ability to capitalize on maintenance through Profile Service.

Conclusion: Building Value Together

Across these projects, one constant emerges: the combination of Prayon Technologies’ process expertise and Profile’s mechanical innovations creates value for producers worldwide.

Today, 70% of phosphoric acid projects worldwide integrate Prayon technologies or equipment. This leadership is not only about efficiency and reliability, itis also about sustainability. Modern production tools must secure longevity while improving environmental impact, helping producers meet both today’s needs and tomorrow’s expectations.