Choose your language

MANUFACTURING ENGINEER

Augusta

Job Details

- Job Location: Augusta

- Position Type: Full-Time

- Education Level: Bachelors

- Travel Percentage: Negligible

- Job Shift: Monday-Friday

- Job Category: Engineering

Description

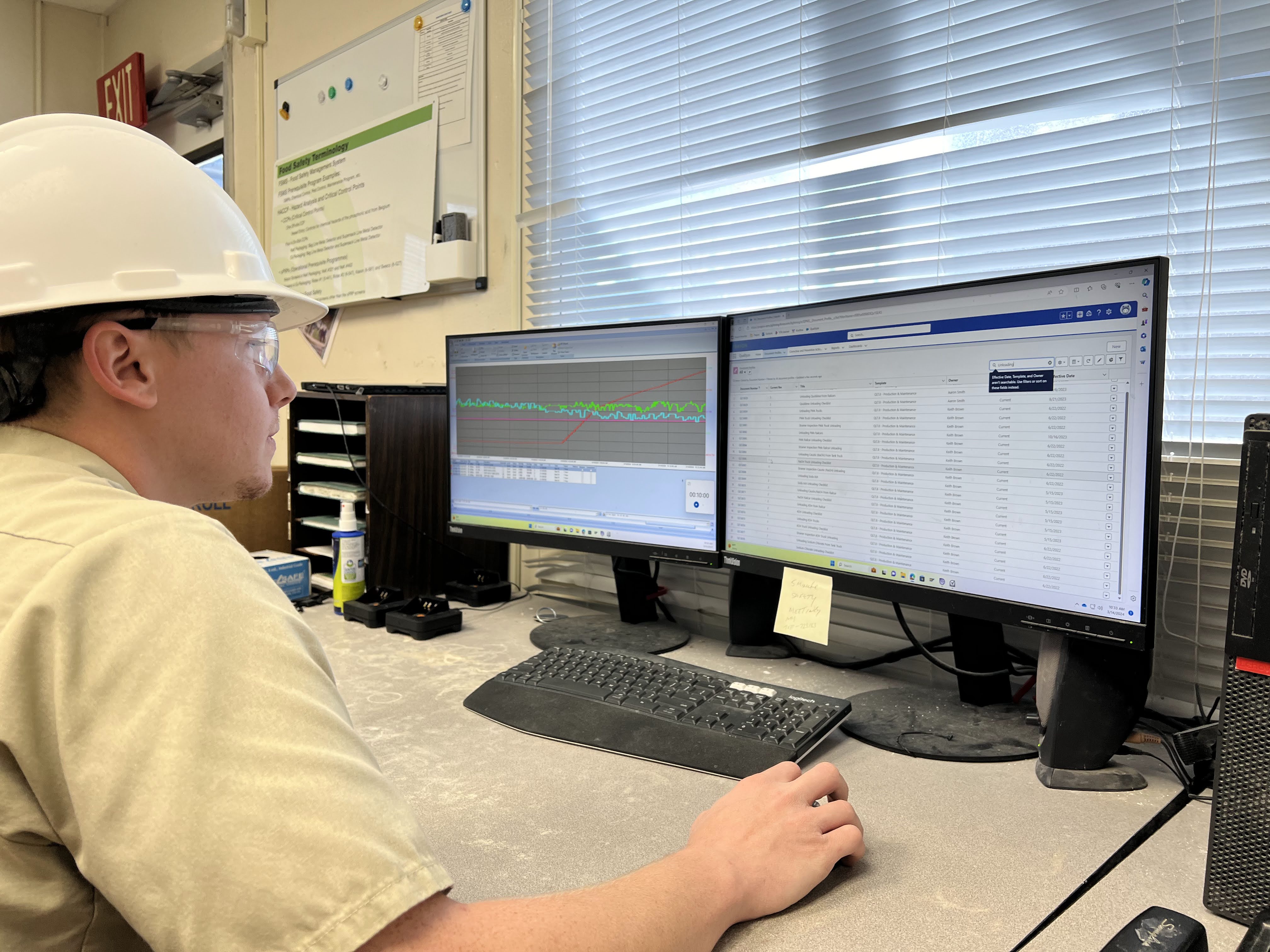

TheManufacturing Engineeris a key technical contributor responsible for supporting daily manufacturing operations and driving continuous improvement initiatives. This hands-on role provides process and performance support across the NaK, Calcium, and Bulk Material production lines, ensuring operations are safe, efficient, and compliant.

Working closely with operations, maintenance, ESH, and quality teams, the Manufacturing Engineer helps resolve issues, implement process improvements, and support capital projects. This role plays a critical part in executing the department’s operational strategy and fostering a culture of performance, ownership, and innovation.

In partnership with the Supervisor, Lead, and Manager, the Manufacturing Engineer also promotes operational discipline and leads the implementation of continuous improvement efforts on the production floor.

Essential Responsibilities & Functionsinclude the following, others may be assigned.

Operational Support & Performance Monitoring

- Provide hands-on technical support to production teams across all manufacturing lines.

- Monitor shift logs, yields, and KPIs to identify and address performance gaps.

- Analyze process data (e.g., throughput, OEE, material losses, energy use) and recommend improvements.

- Participate in daily production meetings and contribute to short- and mid-term planning.

- Maintain and update dashboards and performance tracking tools.

SHEQ Compliance & Action Plan Coordination

- Ensure operational compliance with safety, health, environmental, quality, and food safety standards.

- Participate in incident investigations, audits, and deviation reviews.

- Lead the coordination and follow-up of preventive and corrective action plans.

- Support audit readiness and contribute to documentation and procedural updates.

Continuous Improvement & Reliability

- Lead or support root cause analysis of downtime, quality issues, and other manufacturing or process deviations.

- Identify, proposes and prioritize technical or strategic opportunities for improvement, implement low-cost, high-impact improvements (“quick wins”).

- Collaborate with Maintenance and EHS to address recurring issues and improve reliability.

- Ensure standard operating procedures and production instructions are maintained and updated.

- Train operators and supervisors on process changes and best practices.

- Pilot industrial trials and action plans.

Support execution of plant upgrades and MOCs

- Provide production data and technical input for MOC justifications and project scopes.

- Evaluate the risks associated with projects and prioritize accordingly

- Communicate operational needs to project teams and validate proposed solutions.

- Support project execution, including commissioning, documentation revision, PSSR, and end-user training.

- Track project-related performance metrics and contribute to post-implementation reviews.

Must be able to work in excess of eight hours per day or forty hours per week on any shift or travel as needed. On-call as needed to support 24-hour/7 day per week operational requirements.

Consistently demonstrates prompt, regular and reliable attendance.

Food Safety & Quality Standards

The employee must comply with all applicable food safety and quality standards and requirements.

Supervisory Responsibilities & Functions

This is a non-supervisory role; however, the Manufacturing Engineer serves as a key leader within the department. While they do not have direct reports, they actively support the Manufacturing Manager, Operations Supervisor, and Operations Lead in overseeing the hourly team. Their contributions include participating in hiring, onboarding, training, and providing performance feedback, including escalating disciplinary issues when needed. The Manufacturing Engineer may also assist with developing work plans, assessing staffing needs, setting operational goals, and providing coverage for Operations Supervisors as required. Additionally, they help sustain team performance through coaching, reinforcing expectations, and ensuring compliance with GMP and food safety standards.

Direct Reports: None

Qualifications

Minimum

- Education: Bachelor’s Degree in Engineering

- Experience: Three (3) or more years of experience as a Engineer in a chemical manufacturing setting with demonstrated skills in problem-solving/troubleshooting and continuous improvement with a focus on basic SHEQ including process and food safety related culture.

Preferred

- Education: Master’s degree in Chemical or Mechanical Engineering

- Experience: Minimum plus Experience with SAP, ASPEN or Data Historian Application.

Language Skills

Must demonstrate reading, comprehension, speaking, and writing skills consistent with the required education level. This includes the ability to read, analyze, and interpret general business communications, technical or product information, policies and procedures, and government regulations. Must be able to complete written forms and draft routine to complex procedures, reports, and correspondence. Additionally, must be capable of effectively presenting information and responding to questions in both group and individual settings.

Mathematical Skills

Requires mathematical skills including proficiency in arithmetic, geometry and algebra, with some requirements for calculus and differential equations. Must be able to analyze data, develop equations and perform mass and energy balance calculations.

Computer Skills

Proficient in Microsoft Office applications, including Outlook, Word, Excel, and PowerPoint.

SAP or other ERP experience

Aspen or another historian/trend experience (preferred)

Complexity

The work includes varied duties requiring many different and unrelated processes and methods be applied to a broad range of activities and/or substantial depth of analysis within a particular area. Decisions include areas of uncertainty in approach, methodology, interpretation or evaluation resulting from such elements as continuing changes, technical developments, unknown phenomena or conflicting requirements. The work requires originating new techniques, establishing criteria, or developing new information.The position requires a working understanding of phosphate manufacturing operations and technical troubleshooting skills including a knowledge of chemistry, mechanical skills, basic electrical and instrumentation skills, distributed and PLC process control systems, material science related to phosphates, PFD and EFD drawings, project management, and unit operations. Project development support function requires knowledge of capital project management process that includes a working knowledge of finance, engineering, and construction.

Physical Demands

The work requires both sedentary and limited physical exertion to include sitting; walking; standing; bending; traversing stairs; carrying of light items such as papers, books or small parts; driving an automobile, forklift, etc. Work routinely requires speaking and hearing (expression or exchanging ideas by means of spoken words and perceiving sounds by ear).

Must be able to work long hours in a manufacturing environment that includes high heat and humidity. Must be able to work “hands on” in troubleshooting process and equipment problems. Must be able to climb stairs.

Work Environment

The work environment requires normal safety precautions typical of such places as offices, meeting and training rooms, personal or commercial transportation methods. Requires use of safe work practices with office equipment, avoidance of trips and falls, observance of fire regulations and traffic signals, etc. Generally, the work area is well lighted, heated and ventilated. Also includes work that requires special safety precautions such as working around moving parts, carts or machines or with irritant chemicals. Employee may be required to use protective clothing or gear such as masks, gowns, coats, safety shoes, boots, goggles, gloves, safety glasses or shields.

Augusta en quelques mots

Nos offres d'emploi

Un job passionnant dans un groupe international

Travaillant sur des sites répartis dans le monde entier, chacun de nos experts met à profit ses compétences uniques et son dynamisme contagieux pour améliorer la qualité et l'efficacité des produits que nous proposons. C'est grâce à eux que nous restons à la pointe du marché et que nous pouvons développer les technologies de demain. Mais, afin de continuer à montrer la voie dans notre secteur, nous restons toujours à la recherche de talents.

Envie de nous rejoindre pour faire la différence ?